Welcome to

Shanghai Yi Huan

The Layouts Drawing of ALE

Model200/ 400/500/600/1000/2000

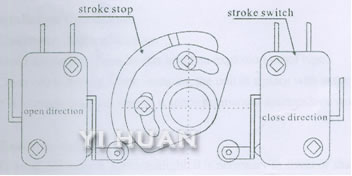

Stroke Stop and Stroke Switch

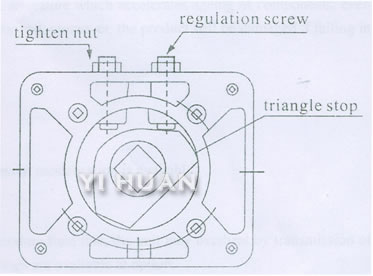

Mechanical position-limiting

- Rotate it to the wholly-open position with handle

- Loosen tighten-nut and rotate regulation screw in order to touch the mechanical link-stopper,then, rotate screw or semi-circle in anticlockwise direction for tightening nut.

- Using same method, operator could regulate mechanical link-stopper at wholly-closed position.

Note: the mechanical position-limiting should lag behind the electric limiting, or else,it would lead to heating of electric machine.

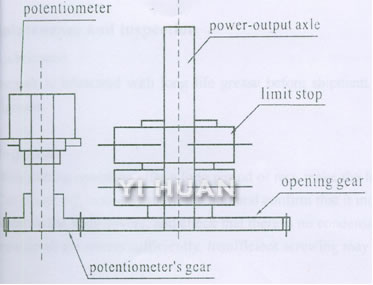

- he resistance value of potentiometer is 1 KΩ,5 KΩ.

- Using handle to rotate valve to wholly-closed position

- Loosen screw of opening-gear and rotate opening gear for regulating potentiometer.

Using universal-meter to measure resistance value between 4 and 5 wiring terminals, and make the resistance value achieve 5Ω, tighten opening gear fixing screw.(if the seven-line connector of intelligent type are connected, please measure the resistance between RV and RS jacks).

Note: operator also could loosen potentiometer for regulation, however, in case of being fixed, operator should take notice of the stitch closure between gears of potentiometer and opening, which can’t be too large or small, or else, it would directly affect the complete-set precision of execution device.

Operation principleTop of page

Operation principleTop of page

The system makes computation between input signals(4~20mA DC) and position signals, then turns the motor in direction to balance them, and stops the motor when they are balanced. The motor torque is transmitted through the worm structure to the actuator shaft. Rotation direction (direct or reverse) is selectable at the setting switch. The backlash revision type potentiometer detects and feedbacks the shaft positions to the control pack. The system always controls shaft position at the correlated rates with input signals.

Installation conditionsTop of pageCautions on indoor installation

- Avoid a hazardous place, as this is not an explosion-proof type.

- Cover whole the unit, when installing the unit in a place with water or material splashes.

- It is recommendable to reserve a space for manual maintenance work. (Depends on installation conditions.)

* Caution on outdoor installation

- To avoid rainwater or direct sunlight, it is necessary to cover or shade whole the unit.(this concerns temperature rise in the unit, and anti-climate property of seals used.)

- It is recommendable to reserve a space for manual maintenance work .(depends on installation conditions)

Note: the shining of sunshine outdoor would lead to high-temperature which accelerates ageing of components, even losing effectiveness; the rain would accelerate aging of rubber-pad, moreover, the product will be damaged if failing in waterproof conduction.

Temperature conditionsTop of pageAmbient temperature

- Ambient temperature range: -30℃~+60℃.

Note: for use under negative temperature, space heater to prevent condensation is available.

*Fluid temperature

- It is occasional that if the actuator is applied to a high temperature fluid line, the unit may

overheat by transmission of line heat. In such a case, use radiation type bracket and couplings are available at option.

- Standard bracket and couplings: fluid temperature max.65℃

- Radiation type bracket and couplings: fluid temperature over 65℃

Maintenance and Inspection:

* Lubrication

The unit is lubricated with long life grease before shipment, and in principle it does not require re-lubrication after shipment.

* Inspection

When starting operation after a long period of rest, make the following confirmation:

- Cut power off, manually drive the unit and confirm that it moves smoothly without eccentricity.

- Remove the body covers, and check that there is no condensation inside, and wiring is proper. After inspection is over, screw up all the covers sufficiently. Insufficient screwing may cause water ingress and troubles.

| Trouble and probable cause | Solution |

| Motor does not start up | |

| Power failed or dropped | Check and supply power |

| Signal failed or dropped | Check and input signals |

| Wire broken or disconnected | Change the wire or re-connect the terminal |

| Thermal protector functioned | Lower the ambient temperature or decrease duty rate. Eliminate overload at valve |

| Limit switches functioned at an intermediate position | Re-adjust the limit cam |

| Motor advancer defective | Change advancer (condenser) |

| Motor is defective or lead wire is broken | Renew an actuator |

| Control pack defective | Change control pack |

| Aperture unfixable (hunting) | |

| Noise on signal line | Check input signal |

| Noise on potentiometer | Change potentiometer |

| Potentiometer and opening gear loose | Check the fixing screws |

| Aperture does not match input signal | |

| A wrong signal input | Check the input signals |

| Improper adjustment of ZERO/SPAN | Re-adjust ZERO/SPAN |

| Potentiometer slipped | Re-adjust the aperture on the potentiometer |

| Aperture signal does not output | |

| Signal wire is broken or connection is not proper | Check the wiring connection |

(Can't find what you need? We may produce it - Contact Us today!)