Welcome to

Shanghai Yi Huan

The Use Specifications Of PT-2B Series Controlling Modle

ModelPT-2B

Main technical specialties

Accepting DC4-20 mA signal from PLC, DCS system or other operating system, PT-2B series smart controlling module powered by an AC220v single alternating voltage controls the actuator to open or close which consists the electric actuator.

- Input voltage range:AC180V~245V.

- The brake function of the controlling module highly improves the precision of valve position controlling.

- Input/output signal through optoelectronic isolating(endure 200 surge voltage)

- 4~20mA position feedback signal load resistance:50Ω~700Ω,precision:5‰; three potentiometer adjuster technology enable 4~20mA feedback finished in one turn which greatly simplify the adjusting process.

- In case of input signal lost, the actuator will choose to keep the valve current position or control the valve to full close/open according to the “signal lost” dials set in the module by the customer in advance.

- Working temperature: -20℃~+65℃

- Metal cover se ZY d with resistance of electromagnetism disturber.

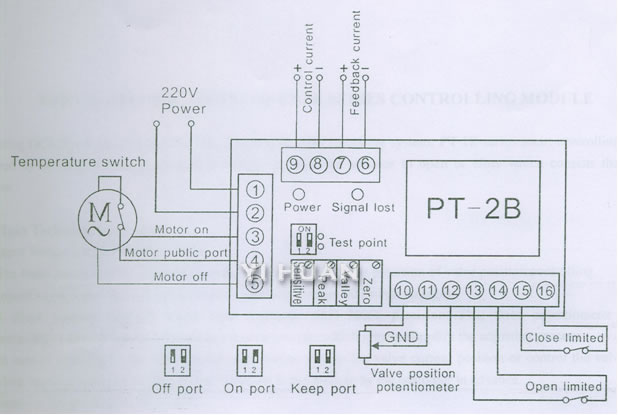

- Connection and Dial Setting

- PT-2B series module should be connected with actuator as shown in the picture-1. the resistance valve should be no less than 1 KΩ.

- Checking the motor connection port of the module by mutineer to ensure no short circles exist.

- If there are no errors after the above inspection, connecting the 220V power supply line.

- Adjusting

- Using the hand wheel gear operation on the actuator to turn the actuator to the middle rotation.

- Set the signal lost dials to “Keep Port”, providing with the 220V electric power without controlling electric current on it, then the “Power Light” and “Signal Lost Light” are being lightened. Then if setting the “Signal Lost” dials to “Open Port” or “Close Port”, the actuator will rotate to open or close direction. While if setting the “Signal Lost” dials to “Keep Port”, the actuator will be stopped. If actuator rotating direction should be opposite, please exchange the connection of “Module On” and “Module Off”.

- When the actuator rotate to close position, adjusts the “Zero” potentiometer to make the voltage between TS1 and TS2 being zero, then adjusts “Low” potentiometer to output the 4mA signal; rotating the actuator to open position, adjusts “high” potentiometer to output the 20mA signal. The above adjustments would be finished in one turn (the “Zero”, “Low” and “High” are all increased in clockwise and reduced in anticlockwise).

- Attention: when the valve position rotating from close to open, the absolute voltage value of the center slider block in valve position potentiometer to ground GND should changes from low or high.

- In order to ensure the position controlling precision of the actuator, sensitive range should be adjusted. Higher sensitive causes higher position controlling precision but also higher surge possibility. While lower sensitive cause’s lower position controlling precision but lower surge possibility. We suggest adjusting to the best position controlling precision without any surge possibility.

Note: All the potentiometers inside this module are multi-coil precision potentiometer (around 25 rounds rotation possible) .plus the 10 to 16port are forbidden to connect any power supply,

otherwise would damage the module.

Port reference tableTop of page

Port reference tableTop of page

Port No |

Description | Port No. |

Description |

| 1 | Input 220VAC | 9 | Control current(4-20mA) "+" |

| 2 | Input 220VAC | 10 | Valve position potentiometer earth lug |

| 3 | Motor on | 11 | Center slide block in valve position potentiometer |

| 4 | Motor public port | 12 | Valve position potentiometer supply port |

| 5 | Motor off | 13 | Open limited port |

| 6 | Feedback current(4-20mA) "-" |

14 | Open limited port |

| 7 | Feedback current(4-20mA) "+" |

15 | Close limited port |

| 8 | Control current(4-20mA) "-" |

16 | Close limited port |

(Can't find what you need? We may produce it - Contact Us today!)