Welcome to

Shanghai Yi Huan

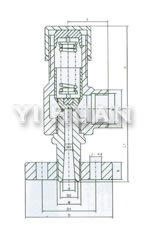

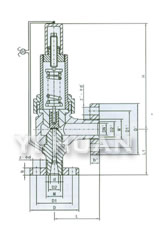

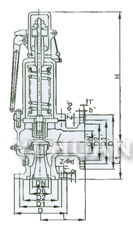

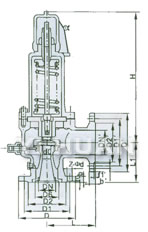

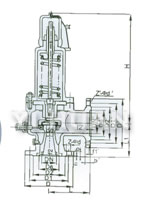

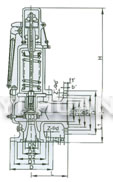

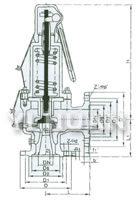

Closed Spring Loaded Low Lift Type-High Pressure Safety Valve

ModelA41Y/A42Y/A44Y/A48Y/

Closed Spring Loaded Low Lift Type-High Pressure Safety Valve applications

A41Y-160/320 types are used for the equipment and pipeline of the air, N2, H2 mixed gas, water etc. medium what the working temperature are less than 200℃. A41Y-160P/320P, A41Y-160R/320R type are used for the equipment and pipeline of the quality with corrode gas and liquid medium what the working temperature are less than 200℃. Take for extra pressure protection devices.

Flange connecting dimensions of comply with Standard of JB/T2769-92.

A42Y-C type are used for the equipment and pipeline of the air, petroleum gas, liquid etc medium what the working tempera-true are less than 300℃.

A42Y-P type and A42Y-R type are used for the equipment and pipeline of the quality with corrode medium What the working temperature are less than 200℃. A48Y is be used in equipments and pipelines of steam, air with operation temperature no higher than 350. Take for extra pressure protection devices.

Flange connecting dimensions of comply with Standard series first of JB/T: -94, Comply with Standard Service of JB/T----94 when more than 6.4Mpa.

A48Y type are used for the equipment and pipeline of the with steam and air etc medium what the working temperature are less than 350℃. A44Y type are used for the equipment and pipeline of the with air and petroleum gas medium what the working temperature are less than 300℃. Take for extra pressure protection Devices.

Flange connecting dimensions of comply with Standard series first and second of JB/T-94 when the pressure less than 6.4Mpa, comply with Standard series second of JB/T-94 when more than 6.4Mpa.

Closed Spring Loaded Low Lift Type-High Pressure Safety Valve brief figure of structure

Closed spring loaded low lift type-high pressure safety valve dimensions (mm)Top of page

Closed spring loaded low lift type-high pressure safety valve dimensions (mm)Top of page

Type |

DN | do | d | M | D | K | Z-∮d | b | d1 | M1 | D1 | K1 | Z1-∮d1 | b1 | L | L1 | ≈H |

| A41Y-160 | 15 | 8 | 20 | M24×2 | 95 | 60 | 3-18 | 20 | / | M33×2 | 36 | / | / | / | 50 | 80 | 85 |

| 20 | 10 | 25 | M27×2 | 95 | 60 | 3-18 | 20 | / | M33×2 | 48 | / | / | / | 50 | 80 | 85 | |

| 25 | 12 | 28 | M33×2 | 105 | 68 | 3-18 | 20 | / | M33×2 | 48 | / | / | / | 50 | 80 | 85 | |

| A41Y-160 | 10 | 8 | 18 | M24×2 | 95 | 60 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 |

| 15 | 8 | 20 | M24×2 | 95 | 60 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 20 | 10 | 27 | M33×2 | 105 | 68 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 25 | 12 | 28 | M42×2 | 105 | 68 | 3-18 | 20 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 32 | 12.14.16 | 37 | M52×2 | 115 | 80 | 4-18 | 22 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 40 | 20 | 47 | M64×2 | 165 | 115 | 6-26 | 28 | 65 | M80×3 | 200 | 145 | 6-29 | 40 | 165 | 165 | 350 | |

| 50 | 25 | 58 | M26×2 | 165 | 115 | 6-26 | 32 | 80 | M100×3 | 225 | 170 | 6-33 | 80 | 165 | 165 | 380 | |

| A41Y-320 | 10 | 8 | 18 | M24×2 | 95 | 60 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 |

| 15 | 8 | 27 | M33×2 | 105 | 68 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 20 | 10 | 30 | M36×2 | 110 | 75 | 3-18 | 20 | 29 | M42×2 | 115 | 80 | 4-18 | 22 | 95 | 100 | 261 | |

| 25 | 12 | 35 | M42×2 | 115 | 80 | 4-18 | 22 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 32 | 12.14.16 | 41 | M48×2 | 135 | 95 | 4-22 | 25 | 50 | M64×3 | 165 | 115 | 6-26 | 32 | 130 | 135 | 285 | |

| 40 | 20 | 58 | M64×3 | 165 | 115 | 6-26 | 32 | 65 | M80×3 | 200 | 145 | 6-29 | 40 | 165 | 115 | 350 | |

| 50 | 25 | 70 | M80×3 | 200 | 145 | 6-29 | 40 | 80 | M100×3 | 225 | 170 | 6-33 | 50 | 165 | 165 | 380 |

| Nominal Diameter DN (mm) |

Dimensions (mm) | |||

| d0 | L | L1 | DN’ | |

| 25 | 15 | 110 | 95 | 32 |

| 32 | 20 | 115 | 100 | 40 |

| 40 | 25 | 120 | 110 | 50 |

| 50 | 32 | 165 | 120 | 65 |

| 65 | 40 | 160 | 135 | 80 |

| 80 | 50 | 170 | 135 | 100 |

| 100 | 65 | 195 | 175 | 125 |

| 125 | 80 | 210 | 190 | 150 |

| 150 | 100 | 255 | 230 | 175 |

| 200 | 125 | 300 | 260 | 250 |

| 250 | 150 | 350 | 320 | 300 |

| 300 | 200 | 380 | 350 | 400 |

| 350 | 300 | 500 | 450 | 500 |

| 400 | 350 | 500 | 450 | 500 |

| Nominal Diameter DN (mm) |

Dimensions (mm) | |||

| d0 | L | L1 | DN′ | |

| 25 | 15 | 110 | 105 | 32 |

| 32 | 20 | 130 | 110 | 40 |

| 40 | 25 | 135 | 120 | 50 |

| 50 | 32 | 160 | 130 | 65 |

| 80 | 50 | 175 | 160 | 100 |

| 100 | 65 | 220 | 200 | 125 |

| 150 | 100 | 285 | 260 | 200 |

| 200 | 125 | 350 | 320 | 250 |

| Nominal Pressure PN (MPa) |

Nominal Diameter DN (mm) |

Dimensions (mm) | |||

| L | L1 | d0 | DN’ | ||

|

1.6 2.5 4.0 |

25 | 110 | 95 | 15 | 32 |

| 32 | 115 | 100 | 20 | 40 | |

| 40 | 120 | 110 | 25 | 50 | |

| 50 | 135 | 120 | 32 | 65 | |

| 65 | 160 | 135 | 40 | 80 | |

| 80 | 170 | 135 | 50 | 100 | |

| 100 | 195 | 175 | 65 | 125 | |

| 150 | 255 | 230 | 100 | 175 | |

| 200 | 300 | 260 | 125 | 250 | |

|

6.4 10.0 |

25 | 110 | 105 | 15 | 32 |

| 32 | 130 | 110 | 20 | 40 | |

| 40 | 135 | 120 | 25 | 50 | |

| 50 | 160 | 130 | 32 | 65 | |

| 80 | 175 | 160 | 50 | 100 | |

| 100 | 220 | 200 | 65 | 125 | |

| 150 | 285 | 260 | 100 | 200 | |

No. |

Name of part | A42Y-C A48Y-C KA42Y-C Materials | A42Y-P/KA42Y-P Materials |

A42Y-R Materials |

DA42Y-P Materials |

| 1 | Nozzle | 2Cr13/1Cr18Ni9Ti | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | ZG1Cr18Ni9Ti |

| 2 | Body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | LCB/ZG1Cr18Ni9Ti |

| 3 | Adjusting ring | 2Cr13/1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 4 | Disc holder | 2Cr13/1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 5 | Disc | 2Cr13/1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 6 | Guide sleeve | 2Cr13/1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 7 | Bonnet | ZG230-450 | ZG230-450 | ZG230-450 | ZG1Cr18Ni9Ti |

| 8 | Spring | 50CrVA | Coated Teflon | Coated Teflon | 50Cr18Ni9Ti |

| 9 | Stem | 2Cr13 | 1Cr18Ni9Ti/1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti/1Cr18Ni12Mo2Ti | 1Cr18Ni9Ti |

| 10 | Adjusting bolt | 45 | 2Cr13 | 2Cr13 | 2Cr13 |

| 11 | Cap | ZG200-400 | ZG200-400 | ZG200-400 | ZG230-450 |

| Sealing surface of material | Depositing satellite | ||||

No. |

Name of part | A48Y-C A44Y-C A42Y-C Materials |

A44Y-P A42Y-P Materials |

A44Y-R A42Y-R Materials |

| 1 | Body | WCB | ZG1Cr18Ni9Ti | CF8M |

| 2 | Nozzle | 2Cr13 | 1Cr18Ni9Ti | 316 |

| 3 | Adjusting ring | ZG2Cr13 | ZG1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti |

| 4 | Disc holder | ZG2Cr13 | ZG1Cr18Ni9Ti | 316 |

| 5 | Disc | 2Cr13 | 1Cr18Ni9Ti | 316 |

| 6 | Guide sleeve | 2Cr13 | 1Cr18Ni9Ti | 0Cr18Ni12Mo2Ti |

| 7 | Bonnet | ZG230-450 | ZG230-450 | ZG230-450 |

| 8 | Spring | 50CrVA | Coated Teflon | Coated Teflon |

| 9 | Stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti |

| 10 | Lever | ZG200-400 | ZG200-400 | ZG200-400 |

| 11 | Adjusting bolt | 45 | 2Cr13 | 2Cr13 |

| 12 | Cap | ZG200-400 | ZG200-400 | 316 |

| Sealing surface of material | Depositing satellite | |||

(Can't find what you need? We may produce it - Contact Us today!)