Welcome to

Shanghai Yi Huan

Metal To Metal Seat Ball Valve

ModelClass 150/300Lb

Metal to metal seat ball valve specifications

High Temperature Service

General soft seated ball valves working temperature is limited up to 400°F, but metal-seated ball valves are guaranteed for a maximum service temperature of 800 °F.

Low Pressure Reliable Sealing

YIHUAN metal-seated ball valves adopt seat spring structure, which can push upstream seat tightly against the ball surface creating a reliable sealing even if extremely low pressure.

Pressure Test

Metal-seated ball valves maximum allowable seat leakage:

Air: ANSI/FCI 70-2 Class V

Absolute Fire Safe Guarantee

YIHUAN metal-seated ball valves are absolute fire safe design. Metal-to-metal contact is designed between ball and seat, where is unconditional fire safe function. Flexible graphite gasket can prevent fluid leakage from between body & seat or body & adapter even if high temperature environments to reach fire-safe purpose. In addition, other sealing components such as stem packing can also reach fire-safe function and prevent external leakage, so all parts of the valve will not be damaged by high temperature service.

Blow-out Proof Stem& Anti-Static Device

As general ball valves, YIHUAN metal-seated ball valves are provided with blow-out proof stem& anti-static device.

Metal to metal seat ball valve product picture

Metal to metal seat ball valve material specificationsTop of page

Metal to metal seat ball valve material specificationsTop of page

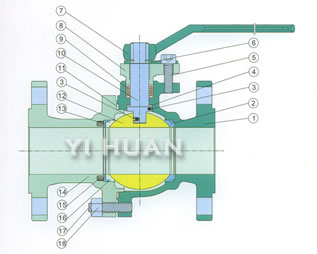

No. |

Part | Material |

| 1 | Body | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 2 | Seat | ASTM A182-F6+STL, 304+STL, F316+STL, F316L+STL |

| 3 | Antistatic Spring | Stainless Steel S.S.316 |

| 4 | Thrust Washer | PTFE PPL |

| 5 | Screw | ASTM A193-B7, B8 |

| 6 | Limited Plate | 1015+Cr. Carbon Steel+Cr. |

| 7 | Lever | A216-WCB |

| 8 | Gland Flange | A216-WCB A351-CF8 |

| 9 | Packing | PTFE Graphite |

| 10 | Stem | ASTM A182-F6, F304, F316, F316L, F304L,17-4PH, F51 |

| 11 | Gasket | Stainless Steel+Graphite S.S.316+Graphite |

| 12 | Ball | ASTM A182-G6+N, F304+N, F316+N, F51+N |

| 13 | Seat Gasket | ASTM A182-F6, F304, F316, F316L |

| 14 | Bonnet | A216-WCB A352-LCB A351-CF8, CF8M, CF3, CF3M, Duplex |

| 15 | Seat Spring | Inconel X-7505 S.S.304 S.S.316 |

| 16 | Seat Sealing | Graphite |

| 17 | Stud | ASTM A193-B7, B7M, B8, B8M |

| 18 | Nut | ASTM A194-2H, 2HM, 8, 8M |

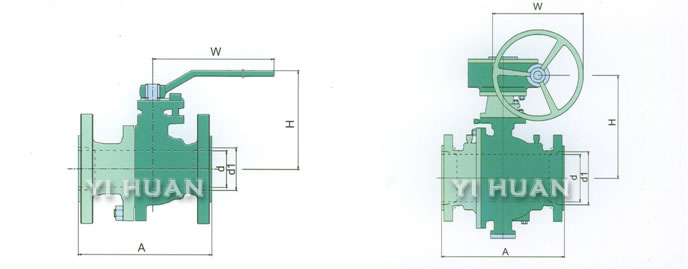

Size |

d | A | H | W | Weight |

| in | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 108 | 75 | 130 | 2.3 |

| 3/4 | 19 | 117 | 84 | 170 | 2.5 |

| 1 | 25 | 127 | 90 | 170 | 3.5 |

| 1-1/2 | 38 | 165 | 127 | 250 | 7.3 |

| 2 | 51 | 178 | 140 | 250 | 9.8 |

| 2-1/2 | 64 | 191 | 164 | 350 | 15 |

| 3 | 76 | 203 | 177 | 350 | 18 |

| 4 | 102 | 229 | 206 | 420 | 33 |

| 5 | 125 | 356 | 292 | 700 | 57 |

| 6 | 152 | 394 | 320 | *1000 | 66 |

| 8 | 203 | 457 | 398 | *320 | 170 |

| 10 | 254 | 533 | 495 | *350 | 255 |

| 12 | 305 | 610 | 580 | *400 | 390 |

| 14 | 337 | 686 | 625 | *500 | 510 |

| 16 | 387 | 762 | 720 | *500 | 820 |

| 18 | 438 | 864 | 770 | *500 | 1010 |

| 20 | 489 | 914 | 840 | *500 | 1828 |

| Size | d | A | H | W | Weight |

| in | mm | mm | mm | mm | Kg |

| 1/2 | 13 | 140 | 75 | 130 | 3.5 |

| 3/4 | 19 | 152 | 84 | 170 | 4.2 |

| 1 | 25 | 165 | 90 | 170 | 5.8 |

| 1-1/2 | 38 | 191 | 127 | 250 | 10.5 |

| 2 | 51 | 216 | 140 | 250 | 14 |

| 2-1/2 | 64 | 241 | 164 | 350 | 19 |

| 3 | 76 | 283 | 177 | 350 | 31 |

| 4 | 102 | 305 | 206 | 420 | 54 |

| 6 | 152 | 403 | 320 | *280 | 135 |

| 8 | 203 | 502 | 398 | *320 | 210 |

| 10 | 254 | 568 | 495 | *350 | 391 |

| 12 | 305 | 648 | 580 | *400 | 550 |

| 14 | 337 | 762 | 625 | *500 | 710 |

| 16 | 387 | 838 | 720 | *500 | 1250 |

| 18 | 438 | 914 | 770 | *500 | 1300 |

| 20 | 489 | 991 | 840 | *500 | 2180 |

| 24 | 591 | 1143 | 920 | *600 | 2930 |

Size |

d | d1 | A | H | W | Weight |

| in | mm | mm | mm | mm | mm | Kg |

| 3/4×1/2 | 13 | 19 | 117 | 75 | 130 | 2.7 |

| 1×3/4 | 19 | 25 | 127 | 84 | 170 | 3.0 |

| 1-1/2×1 | 25 | 38 | 165 | 90 | 170 | 4.3 |

| 2×1-1/2 | 38 | 51 | 178 | 127 | 250 | 9.5 |

| 2-1/2×2 | 51 | 64 | 190 | 140 | 250 | 12 |

| 3×2 | 51 | 76 | 203 | 140 | 250 | 16.5 |

| 4×3 | 76 | 102 | 229 | 177 | 350 | 24 |

| 6×4 | 102 | 152 | 394 | 206 | 420 | 43 |

| 8×6 | 152 | 203 | 457 | 320 | *1000 | 85.5 |

| 10×8 | 203 | 254 | 533 | 398 | *320 | 214 |

| 12×10 | 254 | 305 | 610 | 495 | *350 | 284 |

| 14×12 | 305 | 337 | 686 | 580 | *400 | 418 |

| 16×14 | 337 | 387 | 762 | 625 | *500 | 612 |

| 18×16 | 387 | 428 | 864 | 720 | *500 | 970 |

| 20×18 | 428 | 489 | 914 | 770 | *500 | 1137 |

| 24×20 | 489 | 591 | 1067 | 840 | *500 | 2000 |

Size |

d | d1 | A | H | W | Weight |

| in | mm | mm | mm | mm | mm | Kg |

| 3/4×1/2 | 13 | 19 | 152 | 75 | 130 | 4.0 |

| 1×3/4 | 19 | 25 | 165 | 84 | 170 | 5.0 |

| 1-1/2×1 | 25 | 38 | 190 | 90 | 170 | 7.0 |

| 2×1-1/2 | 38 | 51 | 216 | 127 | 250 | 12 |

| 2-1/2×2 | 51 | 64 | 241 | 140 | 250 | 17 |

| 3×2 | 51 | 76 | 283 | 140 | 250 | 21.5 |

| 4×3 | 76 | 102 | 305 | 177 | 350 | 37 |

| 6×4 | 102 | 152 | 403 | 206 | 420 | 66 |

| 8×6 | 152 | 203 | 502 | 320 | *280 | 164 |

| 10×8 | 203 | 254 | 568 | 398 | *320 | 350 |

| 12×10 | 254 | 305 | 648 | 495 | *350 | 400 |

| 14×12 | 305 | 337 | 762 | 580 | *400 | 590 |

| 16×14 | 337 | 387 | 838 | 625 | *500 | 850 |

| 18×16 | 387 | 428 | 914 | 720 | *500 | 1220 |

| 20×18 | 428 | 489 | 991 | 770 | *500 | 1460 |

| 24×20 | 489 | 591 | 1143 | 840 | *500 | 2220 |

*Trunnion Mounted Gear Operated

Note: 1. The technical data is subject to amend without notice, while is subject to the actual product.

2. If you have any alteration, please note when you ordering.

(Can't find what you need? We may produce it - Contact Us today!)