Welcome to

Shanghai Yi Huan

Pipeline Ball Valve For Long-Distance Transportation

ModelClass 150∼1500Lb

Pipeline ball valve for long-distance transportation features

The ball valve is designed according to the demands of the customers to meet the requirements of cracking-resistance from spur stress under sulfadiazine environment. Therefore under this requirement we accord to the standards concerned of NACE-National Association of Corrosion Engineer strictly in the design and material selecting manufacturing test and surface-treating and lacquer-finishing process.

The ball valve series not only bears wide range of selected materials. Furthermore, the internal components of the valve are all nickel-plated on surface or made of the material 316, and the seal ring is made of the special polymeric material. Therefore, the valve not only features by favorable anti-corrosion and sulfide-resistance capacity. The fine fire-proofing, static-prevention and sealing performance are also enjoyed by it. With wide range of suitable pressure and temperature, the valve features by both all-diameter types and crinkled-diameter ones with diversified applicable driving units. It is a kind of ideal choice in chemical industry, petroleum refining industry, mining and conveying system of natural gas etc.

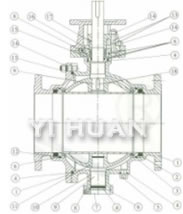

Pipeline ball valve for long-distance transportation brief figure of structure

Pipeline ball valve for long-distance transportation main functionsTop of page

Pipeline ball valve for long-distance transportation main functionsTop of page

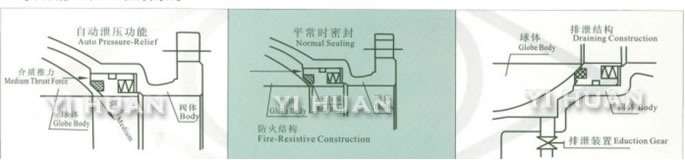

| The pressure of the medium would press the valve seat off from globe body to make a auto-decompression realization when the pressure of the medium remained in the lumen of the valve increases abnormally caused by temperature shift. The seat reset automatically after decompression. | The valve is stall reliable on occasion of fire hazard happens or the seal ring on the valve seat burned or softened caused by abnormal temperature-rise. Meanwhile, the contact of natal against metal by the seat and globe body would be made up to prevent the fire from expanding. This course meets fully the API 6FA. | After the education gear being screwed-off, the valve seat could be checked for leakage, and vented to reduce the medium from polluting the valve. When the valve stays at full-open or full-close position under operating model, the stuffing box on stem could be replaced. |

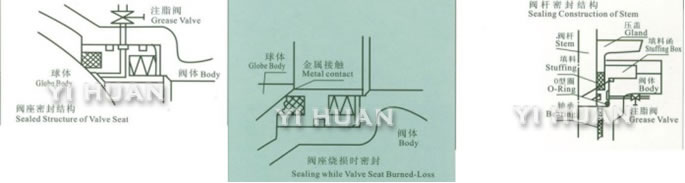

| Besides normal sealing measures, the specially-mounted auxiliary sealed construction on the valve seat can work to first-aid the leakage caused by the damage of the seal ring. | The double sealing of stuffing PTFE and O-ring is applied for sealing the part of stem, thus this measure is applicable especially for gaseous medium. The high-quality self-lubricating bearing SF is utilized on the motion parts of the handle to minimize the coefficient of friction and reduce operating physical force. |

NO. |

Accessory name | Material | |

| GB | ASTM | ||

| 1 | Body | WCB A105 | A182 F316 |

| 2 | Spring | 60Si2Mn | 316 |

| 3 | Sealing Ring | RPTFE | |

| 4 | Gasket | Graphite stainless steel | Graphite+316 |

| 5 | Blow off screw | 25 | 316 |

| 6 | O-Ring | Rubber | Rubber |

| 7 | Bottom cover | A105 | 316 |

| 8 | Screw | 35 | 316 |

| 9 | Stem | 2cr13+nickel coated phosphorus | 316 |

| 10 | Sliding bearing | PTFE& stainless steel | 316+PTFE |

| 11 | Ball | A105 | A182 F316 |

| 12 | Seat | A105 | 316 |

| 13 | Stud | 35CrMoA | 316 |

| 14 | Nut | 35 | 316 |

| 15 | Cover | A105 | 316 |

| 16 | Stuffing | PTFE | PTFE |

| 17 | Gland | WCB | A216-WCB |

| 18 | Key | 45 | 316 |

PN (Mpa) Nominal pressure |

The highest | Test pressure | Pressure class | The highest | Test pressure | ||||

| (Mpa) | Shell | High-pressure liquid sealing |

Low-pressure heretic sealing | (Mpa) | Shell | High-pressure liquid sealing |

Low-pressure heretic sealing |

||

| 1.6 | 1.6 | 2.4 | 1.76 | 0.6 | CLASS150 | 1.94 | 2.94 | 2.16 | 0.6 |

| 2.5 | 2.5 | 3.75 | 2.75 | CLASS300 | 5.1 | 7.67 | 5.62 | ||

| 4.0 | 4.0 | 6.0 | 4.4 | CLASS600 | 10.2 | 15.3 | 11.23 | ||

| 6.4 | 6.4 | 9.6 | 7 | CLASS900 | 15.1 | 23 | 16.85 | ||

| 10..0 | 10.0 | 15 | 11 | CLASS1500 | 25.1 | 37.5 | 27.5 | ||

| Applicable Specification |

Physical dimension follows | GB12221-89 ANSI B16.10 | |||||||

| Flange dimension follows | JB79-59 GB 9113 HG20592-97 ANSI B16.5 | ||||||||

| Welding standard follows | GB12224-89 ANSI B 16.25 | ||||||||

| Test and inspection follows | JB/T 9092-99 API 598 | ||||||||

| Applicable Operating Model |

Applicable medium | Natural gas, liquefied gas, petroleum and other medium | |||||||

| Applicable temperature | -28℃~≤150℃ | ||||||||

| Driving manner | Worm gear, air operated, electric driving, combined air and hydraulic driving etc. | ||||||||

| Please refer to the sample book of form of Main Types and Connecting Dimension for particular installation dimension | |||||||||

(Can't find what you need? We may produce it - Contact Us today!)