Welcome to

Shanghai Yi Huan

Orbital Ball Valve

ModelGQ40Y/F/H GQ41Y/F/H

Orbital ball valve features

a. Non-abrasion design for on off, which resolves the problem of mutual abrasion fully affecting sealing performance of sealing surface in the traditional valves.

b. Uploading construction, with which the valves on pipelines could be checked online and repaired directly. Thus the engine’s stopping could be minimized creatively to reduce the production cost.

c. Single-seat design, which resolves those problems affecting safety caused by abnormal temperature-rise of the medium in the lumen of the valve.

d. Low tensional moment design, with which the stem with structure designed specially could open or shut down with a merely small hand-wheel valve.

e. Wedge-type sealing construction. Traditionally, the valve would be sealed through the mechanical force provided by the stem to wedge-press the ball onto the valve seat. With this design, the sealing performance of the valve would never be influenced by the fluctuation of the pressure difference in pipeline. And the performance would be maintained reliably under all the operating models.

f. Self-purging construction of sealing surface. The fluid inside the pipeline would pass through evenly by 360° room, and along the sealing face on the globe body when the body leaves the seat shiningly. This design not only resolves the problem of scouring on parts on the valve seat by high-speed fluid but also washing away the piled-up matters on the surface to realize self-purging.

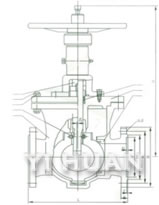

Orbital ball valve brief figure of structure

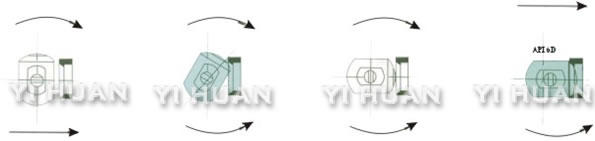

Orbital ball valve operating principlesTop of page

Orbital ball valve operating principlesTop of page

| a. Rotate the hand-wheel clock- wisely while the valve stays at full-open state. After the stem begins to move downwards and brings along the globe body to rotate under the concerted running of valve stem nuts and block bearing. | b. Continuously rotate the hand-wheel, and then the cam-slot track with fine helical-curve would interact mutually with the guide finger embedded inside the track to drive ceaselessly the globe body rotate clock -wisely with the stem. | c. When the valve is about to shut-down, the stem would bring along the globe body to rotate for 90° rod; under the condition that the two parts bears no abrasion completely against the sealing surface of the seat. | d. Continue to rotate the hand-wheel, and then the again-descended stem would press the globe body mechanically to make it contact with the seat closely. Thus the sealing effect would be realized. |

| h. Continuously rotate the hand-wheel, as long as the stem rises to the limit position, at this time, the ball has also reversed along with the handle for 90° stem, and the valve has stayed already at the full-open position. | g. When the valve is about to open, the cam-slot track with fine helical-curve would interact mutually with the guide finger embedded inside the track to drive ceaselessly the globe body rotate counter clock-wisely under the conditions that the mentioned parts bears no abrasion completely against the sealing surface of the seat. | f. Continuously rotate the hand-wheel, hereafter the stem would bring along the globe body leave the seat w shiningly hile going-up. | e. Rotate the hand-wheel counter-clock-wisely while the valve stays at the full-close position. Therefore the handle would go up and drive the globe body to rotate under the concerted work by the stem nuts of the valve and the block bearing. |

Main types |

Accessory name | Materials | |||

| GQ40Y/F/H GQ41Y/F/H |

Body, bonnet | WCB | ZG1Cr5Mo | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti |

| Ball | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | |

| Stem | |||||

| Sealing surface | Cemented Carbide Alloy steel | ||||

| Guide finger | 2Cr13 40CrMn | ||||

| Stem nut | Cast manganese brass | ||||

| Bolt | 35 | 1Cr18Ni9Ti | |||

| Nut | 35 45 | ||||

| Stuffing | PTFE Graphite ring | ||||

| Gasket | Graphite wrapped-gasket Graphite combined gasket | ||||

| Handle | Able to forge iron | ||||

Design Reference |

GB | API |

| Structural Length | JB/T 7745 GB/T 12221 | ANSI B16.10 |

| Connecting Flange | GB/T 9113 JB/79 HG20592 | ANSI B16.5 |

| Butt-welding ends | GB/T 12224 | MSS SP 44 ANSI B16.25 |

| Test & Inspection | JB/T 9092 | API 598 |

Notes: The sizes of serial valve connecting flange and butt-welding end can be designed according to customer’s requirements.

Orbital ball valve performance specifications of the productsTop of pagePressure grade |

Test pressure | Suitable environment | |

| Shell test | Sealing test | ||

| 1.6 | 2.4 | 1.76 | The occasions such as inflammable, easy to exploit, easy to volatilize, easy to get together, and hyper toxic occasion, etc. |

| 2.5 | 3.75 | 2.75 | |

| 4.0 | 6.0 | 4.4 | |

| 6.4 | 9.6 | 7.04 | |

| Class 150 | 2.94 | 2.2 | |

| Class 300 | 7.5 | 5.5 | |

| Class 600 | 15.0 | 11.0 | |

| Applicable temperature | -196℃~≤550℃ | ||

| Applicable medium | Water, oil, natural gas, all kinds of soft medium and suspension, etc. | ||

| Driving means | Manual, Motor driving, Pneumatic | ||

Class |

Main Dimension |

Nominal diameter (mm) | |||||||||||||||

| 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | ||

| PN1.6Mpa | L | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | 1100 | 1200 | 1250 |

| H | 24 | 260 | 307 | 360 | 410 | 483 | 412 | 543 | 581 | 617 | 672 | 723 | 758 | 791 | 828 | 870 | |

| Kg | 09.5 | 16 | 19 | 28 | 30 | 41 | 55 | 78 | 115 | 215 | 270 | 385 | 502 | 876 | 980 | 1240 | |

| PN2.5Mpa | L | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | 1100 | 1200 | 1250 |

| H | 260 | 280 | 320 | 360 | 430 | 460 | 525 | 567 | 604 | 642 | 695 | 742 | 781 | 815 | 864 | 905 | |

| Kg | 9.5 | 16 | 19 | 28 | 30 | 45 | 59 | 82 | 121 | 230 | 289 | 402 | 540 | 913 | 1120 | 1280 | |

| PN4.0Mpa | L | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | 1100 | 1200 | 1250 |

| H | 260 | 280 | 320 | 360 | 436 | 492 | 527 | 607 | 649 | 701 | 750 | 750 | 790 | 832 | 875 | 910 | |

| Kg | 10 | 17 | 20 | 25 | 32 | 45 | 59 | 82 | 115 | 230 | 295 | 402 | 540 | 913 | 1124 | 1348 | |

| PN6.4Mpa | L | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | 1100 | - | - |

| H | 280 | 300 | 329 | 365 | 450 | 509 | 541 | 663 | 725 | 781 | 790 | 806 | 821 | 858 | - | - | |

| Kg | 10 | 17 | 20 | 25 | 32 | 52 | 68 | 106 | 168 | 281 | 355 | 498 | 689 | 1134 | - | - | |

| 150Lb | L | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 356 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 9147 |

| 300Lb | L | 165 | 178 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 |

| 600Lb | L | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 |

(Can't find what you need? We may produce it - Contact Us today!)