Welcome to

Shanghai Yi Huan

Primary Structure、Functions And Features Of Ball Valve

Features of ball valve

Ball Valve is used widely in the fields such as petroleum melting, chemical industry, paper making, and pharmaceutical industry, food industry, waterpower, electric power, city planning, steel & iron etc. Among them the sculpture-resistance series ball valve is applicable especially for Natural Gas Long-Distance Transportation containing suppurate hydrogen medium with many impurity and serious corrodibility.

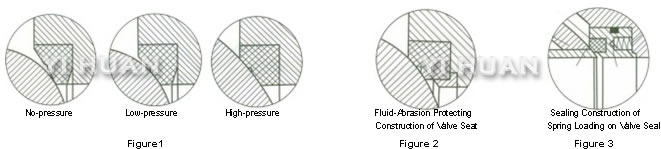

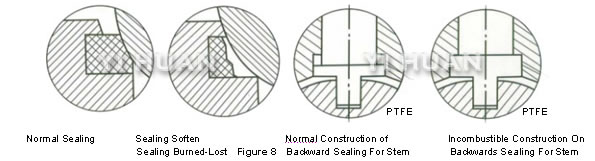

Sealing structure of valve seat

The elastic double-layer seal ring is applied specially in designing the flat ball valve to reduce friction between globe body and seal ring to reduce the physical operating force. The contact area of the seal ring against the globe body is small when the medium pressure is small comparably as well. Therefore, the relative higher specific pressure of sealing is featured by ensuring the positive sealing. And the area would be increased correspondingly when the pressure becomes larger. In this situation the seal ring can hold thrust force from the medium without being damaged, while the positive sealing state would be maintained. (As shown in Figure1)

The fluid-abrasion designed specially protecting construction of valve seat could prevent effectively the abrasion from liquid medium for the service life of sealing rings if the scouring force of the medium is relatively high. (As shown in Figure2)

For the ball valve applied in low-pressure. In the conditions of extra-low-pressure or vacuum operating, the sealing construction designed specially for spring-loading valve seat would maintain the long-term service of the valve. Because the pressure from the medium itself could not ensure the positive sealing of the seat, the pre-tightening force would be weakened unavoidably after long-term performance. (As shown in Figure3)

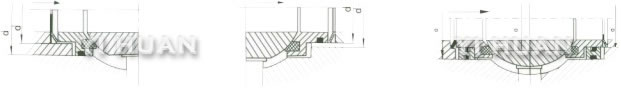

Different sealing is provided for choice with regards to diversified pressure required by the fixed-type ball valve:

a. Sealing on suction end: The piston effect would be realized through the pressure from headrace medium against the area difference of d 1 to d. Thus it would cause intimate contact from valve seat to globe body until be sealed.

b. Sealing on discharge End: The piston effect would be realized through the pressure from lumen medium of the Body against the area difference of a1 to d. Thus it would cause intimate contact from valve seat to glob body until be sealed.

c. Two-way sealing on both suction and discharge ends; the piston effect would be realized through the pressure from both the headrace medium and the lumen medium of the Body. Thus it would cause intimate contact from valve seat to globe body until be sealed, because of d1>d2>d3 and the area difference of d1and d2, and that of d2 and d3. (As shown in Figure4)

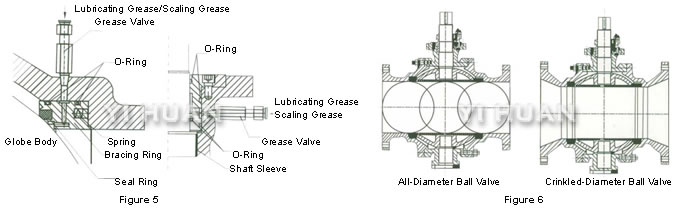

Auxiliary sealing constructionTop of page

Auxiliary sealing constructionTop of page

The grease valve could be mounted additionally on those parts requiring sealing process as valve seat or stem of the ball valve as required. The sealing grease could be rolled into the grease valve if some leakage happen caused by scratching on related sealing place to realize instantaneous sealing effete.(As shown in Figure5)

All-diameter construction & crinkled-diameter construction for the ball valve

The two series of the ball valve consists of the all-diameter valve and the crinkled-diameter one. It is provided for the valve as required, with the minimum fluid resistance and facilitated pipeline-cleaning system. The all-diameter ball valve features by identical inside diameter of the passage to that of the pipeline. While crinkled-diameter construction features by much smaller fluid resistance and 30% discount of less weight than that enjoyed by the cut-off valve of identical caliber. With the production cost and price reduced greatly. This kind of valve is enjoying more popularity. (As shown in Figure6)

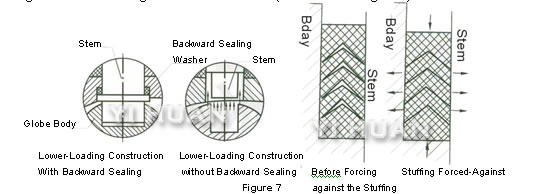

Extruding-protection、valid sealing construction for the stem

Backward sealing construction with lower-load and sealing washer provided with she Stem. The sealing free from the backward sealing process would increase in company with the medium pressure inside the valve pocket to maintain the sealing effect of the stem and ensure the handle rush out if some abnormal lifting pressure happens. The V-structure is also associated with the design of the loading material to transfer effectively both of the medium pressure inside the pocket and the locking force on the external gland to the sealing force on the handle.(As shown in Figure7)

Incombustible construction

Incombustible construction would provide the ball valve’s design as required. Should seal rings be burned in fire, all the sealing parts of the ball valve would form a kind of hard-sealing construction of metal against metal to stop effectively the pervasion of the medium in the valve and aggravation of the fire. (As shown in Figure8)

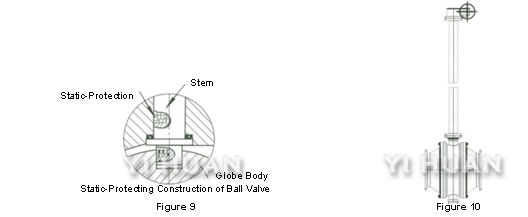

Static-protecting construction

The ball valve could be designed as static-protecting construction as required, namely. It can mount conductive spring between the globe body and Stem, or between the stem and body. Thereafter the static engendered during opening the valve could be conduced to pipelines then earth through the preset static passage to clear static away. The design works to prevent of igniting combustible medium by static fire striking for the system safely. (As shown in Figure9)

Earthling construction

The ball valve could be designed as lengthen construction of stem as required for favorable application in places carting pipelines or installing laying works. (As shown in Figure10)

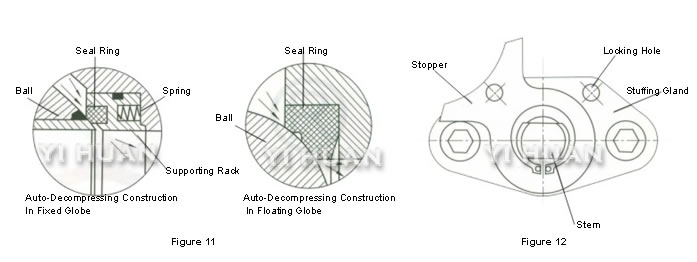

Auto-decompressing construction

The medium in lumen would press the valve seat backwards through its own thrust force to realize auto-decompression for the safety of the body if some abdominal pressure-rise caused by the gasification of the liquid medium detained in the valve pocket from temperature rise. (As shown in Figure11)

Disoperation-protecting construction

Locking holes are provided in the fully-open or full-close position of the valve to realize locking-up motion for safety if some incorrect operations happens to the valve caused by outdoor installation. It is operated by non-staff, or the valve is easy of millrun cottoning through the impaction of the handle in the situation with intensive vibration. (As shown in Figure12)

Flange-connection floating ball valve ralated productsTop of page

Flange-connection floating ball valve ralated productsTop of page

(Can't find what you need? We may produce it - Contact Us today!)